|

Name of product: Round Decorative Decor Idea of creating the product: For many years, KIMA has been creating many kinds of product with different form: square, round, hexagon, oval, etc. But all the products are different from design to the decoration on the surface of product. What is more, KIMA has paid great attention to create the form of product that is suitable to use. So KIMA design a product that is convenient in the family. The design is simple, we can place it on a stand. It will be an art work for decorating in the kitchen or in the sitting room.

Choosing material: - Material to make the products is industrial wood, which are popular in tropical forest. It is processed basing on designs and moistened for anti-bacterial purposes. Then it is processed making lacquer in accordance with the process of KIMA to make it not be curved, cracked, broken and stand in the worst weather in almost the countries. - KIMA decorates the product with the shape of plants and flowers. When making decoration KIMA uses: paint, eggshell, palette, gold and silver, all the materials are from nature so that they do not have impact on user.

Method: All of the products are hand-made Note during producing: Choosing materials which do not have impact on environment and health of user. |

|

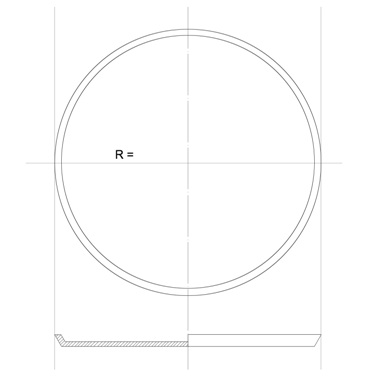

Technical drawing |

Code |

Size |

Detail price |

Whole sale Price |

Net weight |

|

R230 |

R=30 |

|

|

0.50 |

|

R232 |

R=32 |

|

|

0.65 |

|

|

R234 |

R=34 |

|

|

0.75 |

|

|

R236 |

R=36 |

|

|

0.85 |

|

|

R238 |

R=38 |

|

|

0.95 |

|

|

R240 |

R=40 |

|

|

1.20 |

|

|

R242 |

R=42 |

|

|

1.30 |